Custom EVA Case Manufacturer

Bring Your Case to Life with Ease

Transform your EVA case customization into a dynamic and vibrant experience with our simple and efficient process, empowering your brand to stand out.

- Sustainable Materials

- Creative Design

- Fast Prototype

Discover EVA Case Solutions for Your Specific Market

Customize EVA cases that are designed to provide superior protection for your items while enhancing your unique brand image.

Logo Branding

Logo Branding

Exterior Material

Exterior Material

Foam Inserts

Foam Inserts

Pocket Design

Pocket Design

Accessories

Accessories

Create the One-of-a-kind Case

for Your Products

Stand out from the crowd, and build durable, stylish, and functional cases tailored to your brand. A rich portfolio of custom options is available for your projects, from interior to exterior.

- Free design for layout checking in 2 days

- Low tooling cost

- Fast prototyping in 7 days

- Free samples in stock

- Limitless custom options

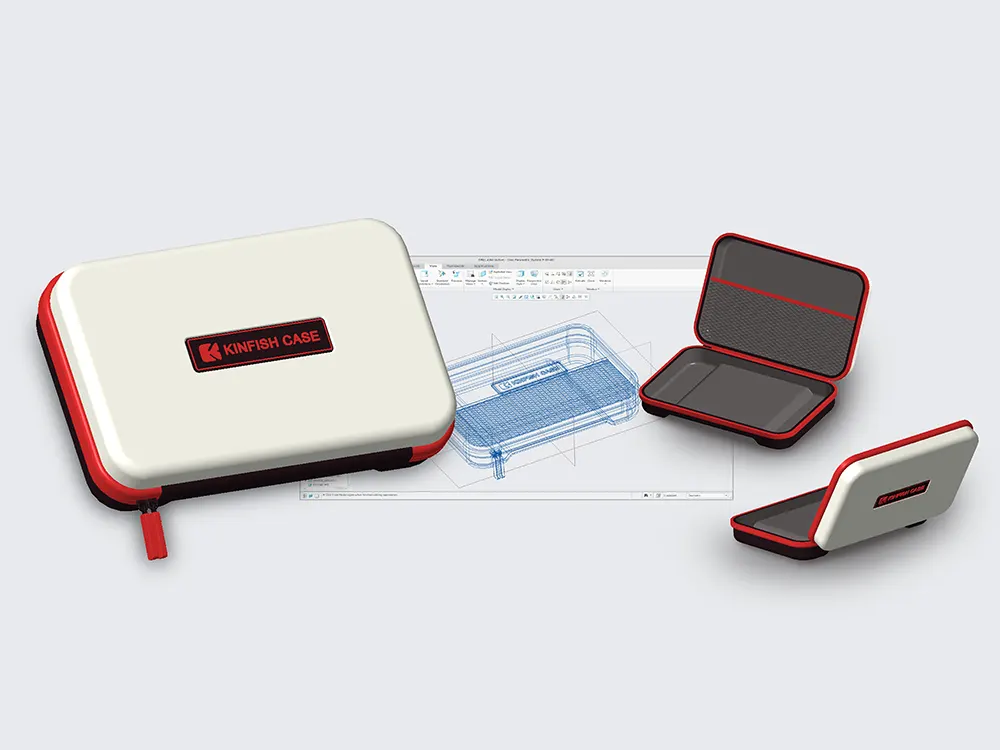

About KinFish Case

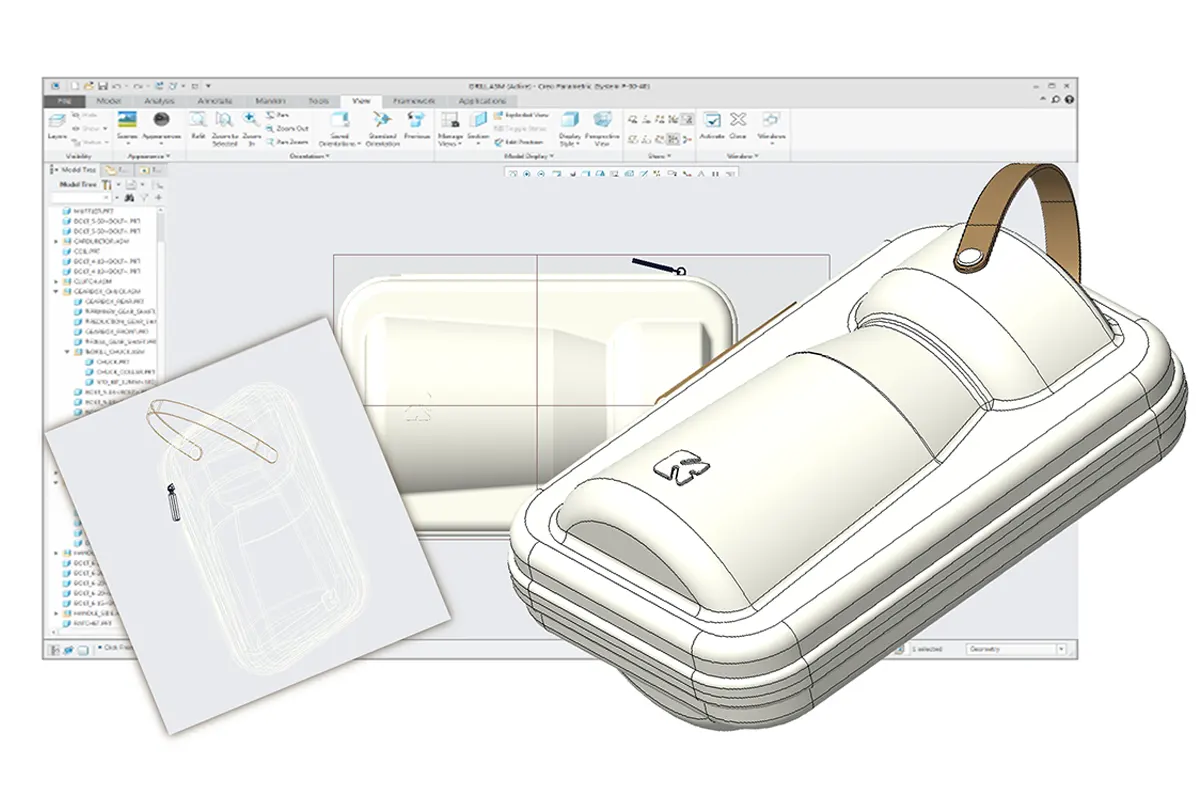

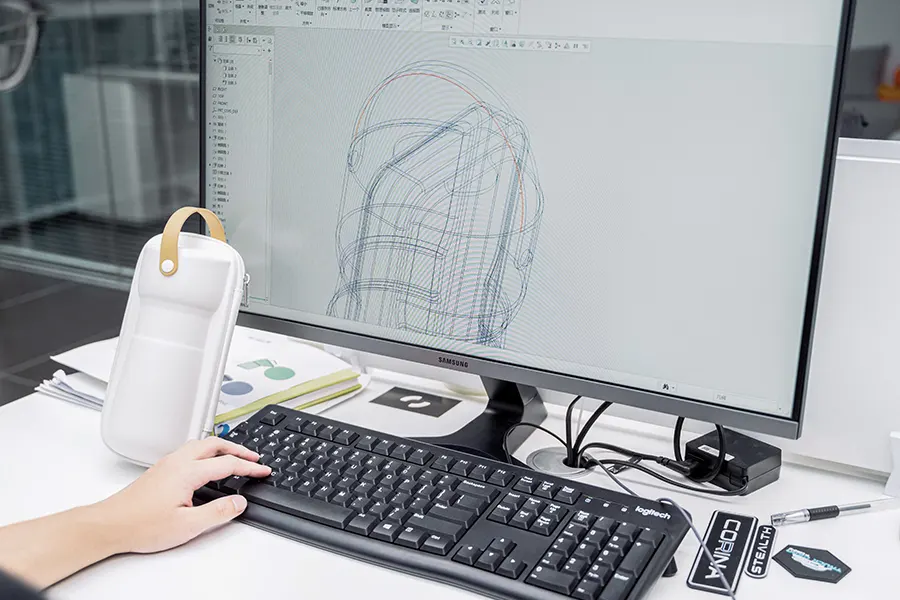

Design EVA Cases

with Precision and Care

For KinFish, constructing an EVA case parallels building a house, as both require thoughtful structural design, efficient space utilization, dependable materials, and precise techniques.

An exceptional EVA case delivers secure and comfortable compartments for diverse items, akin to how a well-crafted house provides cozy rooms for its inhabitants. Attention to detail, rigorous quality control, and customer needs guide our approach to crafting your case.

Our experienced experts will serve as your creative partners, accompanying you throughout the entire process until your masterpiece is in your possession. Let us transform your vision into reality and illuminate your brand’s brilliance!

Explore How Our Solutions have Helped Brands like Yours.

Each brand has its own personality and unique needs. Our team of creative experts excel at generating practical and innovative solutions tailored to you.

Streamlined Production Process

Just a few steps for you to start! Gain a glimpse into the process behind the creation of your custom EVA cases.

1. Consultation

Schedule a video call, if necessary, so that we can have a better grip at your ideas.

2. Design & Presentation

Upload your file. If you don't have one, you got us. We will align with your needs and provide 3D rendering services.

3. Get Your Custom Quote

With your confirmation of all design aspects, we'll develop a pricing quote for you based on your needs and budget.

4. Prototype Development

In 7 days, you will get a prototype of the EVA case and test it for fit, functionality, and durability.

5. Manufacturing & 100% Inspection

Our skilled craftsmen will proceed with the manufacturing process, ensuring strict adherence to quality standards at every stage.

6. Delivery & Support

Ding-dong! For bulk production, it takes around one month for you to receive your custom EVA cases. Ongoing support is available if you have any concerns.

Testimonials